Insulators

XPS Foam Board (3x 2"x4'x8' panels)

- Price

- $20 each

- Buy From

- Local Home Improvement Store

This is just enough to do the main "big" wall gaps like I did. You'll need more if you use it elsewhere.

Thinsulate SM600L (30 linear feet)

- Price

- $300

- Buy From

- eBay

Again, only enough to do the cavities with the XPS already in place. A full van would need about 70-80 linear feet.

EZ-Cool Low-E (100 sqft)

- Price

- $85

- Buy From

- Amazon

I might get a little extra in future for making window shades.

Noico 80 mil (36 sqft)

- Price

- $70

- Buy From

- Amazon

Sound dampening material. You don't need full coverage, just some on each panel.

Adhesives

3M 90

A great general-purpose spray contact adhesive. Used for the Thinsulate.

3M 78

- Price

- $25

- Buy From

- Amazon

Specialist spray contact adhesive that will not dissolve polystyrene (XPS) like most do.

Insulation is your friend when you want to keep a camper van cool in summer or warm in winter, though it's an imperfect science - you can never stop all heat transfer, just get to a point where you're reasonably happy with it.

I think I'm happy with where I got to, but it was a bit of a journey. My insulation materials are:

- Noico 80 mil as the initial sound dampening layer on the sheet metal

- 2" XPS foam board as the primary insulator for the big wall cavities

- Thinsulate SM600L as the primary insulator everywhere else

- EZ-Cool Low-E as the conductive and radiant barrier on places without room for other insulation (the "ribs")

Sound Deadening

Outside noise is your enemy in many situations, and especially when you're in a thin-walled metal box and trying to drive or sleep.

The Noico was my primary deadener here, as it changes the frequencies the sheet metal of the van resonates at to be much lower and harder to hear (and absorbs vibrations faster). It's relatively easy to install - cut with a craft knife, slap some on each sheet metal panel (30-40% coverage is fine!) and then press it in with a heavy metal roller.

The Thinsulate was not initially planned as acoustic insulation (as I hadn't planned it at all!), but it does a really fantastic job of it and honestly might be enough all by itself. More about installing that below.

XPS Foam

I started out using 2" thick XPS foam to insulate the big main panel sections of the van's interior (where the windows would have been installed if it was a passenger van).

While it will leave pink foam crumbs absolutely everywhere, it's easy to cut and shape - a circular saw goes through it like butter for big, regular cuts, and any wood saw easily cuts and shapes corners or smaller shapes.

To stick it to the van's walls, I used a combination of 3M 78 (which is a version of 3M 90 that's guaranteed not to dissolve polystyrene) and some Great Stuff expanding foam around the edges to hold it in place. There's a slight curve to the walls, so I used some heavy objects (such as my water tank) to hold it against the curve while the glue cured.

While XPS is great, it has two main issues:

- The rigidity of it makes it hard to slide it into small crevices and insulate the rest of the van that isn't big, open panels

- Its maximum service temperature is 165°F, and it begins to melt at 195°F. This is less than ideal inside a dark-coloured metal-skin vehicle.

For these reasons, I switched to Thinsulate (below) for the rest of the insulation. I left the XPS in place - the van is designed so I can get to the walls relatively easily (I'm designing with maintenance in mind), so if I do have to rip the XPS out and replace it, it won't be too difficult.

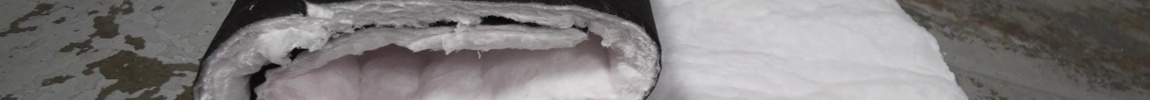

Thinsulate

Thinsulate is a brand name I'm used to from clothes and shoes, so imagine my surprise when I found that they sell giant rolls of the stuff (as Thinsulate SM600L) designed for installation in vehicles.

It's expensive, but this stuff is basically dark magic:

- At 1" thick, it has a similar R-value to 1" thick XPS foam

- It's highly flexible and basically a fabric

- It can take on a bit of water and evaporate it no problem without growing mould

- It also deadens noise very significantly

I used Thinsulate for the rest of the van - all the small cavities, the roof panels, and various small bits around the door (and inside of it too once I get the panel off). I would absolutely go back and use it for the entirety of the van if I hadn't already installed the XPS foam (and also maybe considering the price difference, especially considering the double layer I'd need to match the 2" foam board).

Some cavities you can just stuff it in and it doesn't even need adhesive - everywhere else I used a bit of 3M 90. I adhered the white, fluffy side to the van surfaces, which seemed to work well.

It's not super easy to find, but there's sellers on eBay and Amazon Marketplace who will happily ship you reasonable-sized rolls of the stuff.

EZ Cool Low-E

Low-E is a thin radiant and conductive barrier, and I basically used it in a "some insulation is better than none" approach in all the areas where there wasn't enough depth to fit more "real" insulation - on the structural ribs, around the doorframes, and similar places.

It's incredibly easy to use, and just cuts with a pair of scissors. You can use adhesive if you like, but I secured mine behind various bits of framing track and other bolts as part of my maintainability-oriented design.

Metal Framing

If you're using metal framing (like I am) for the interior framing of the vehicle, it's important to also insulate that from the vehicle to avoid making a thermal bridge from outside straight into the frame of your bed or your chairs.

For this, I did two things:

- All the metal rails the framing is attached to are secured to the van with a layer of Low-E sandwiched between the rail and the wall

- All the bolts from the rails into the van have plastic washers so there's never a full metal path

It's not perfect, but it'll do. I'll report back once the van is more built out and has experienced proper weather as to how it does.

Conclusion

Honestly, that's kind of the approach I have to all the insulation here - it's not perfect, but it seems more than sufficient, and I have the larger Propex furnace to install so I can always out-heat any overlooked insulation gaps on those first few trips and then come back and fix it later. I imagine I'll be taking my infrared camera along those first few times so I can visually see exactly what my handiwork looks like!

There's also a few other things to do in future - windows are the biggest thermal bridge of all in a van, so I'll be sewing some Thinsulate and some Low-E into window covers at some future point, and I may also want a curtain or something between the living area and the driving cab, just because I can't insulate that area nearly as well.

You can see even more blog posts about the van build on its category page, and get updates via my YouTube channel, Twitter, or blog RSS.